Impact Testing

CAUTION!:

ED&D is the only company in the world currently supplying safety products that actually meet or exceed the specified Rockwell hardness’s that are called for in the standards. Manufacturing to these specifications is an extremely difficult process. In addition, we rely on external laboratories that specialize in Rockwell hardness to verify and certify our results. These are corners our competitors’ often cut, but are vital toward providing equipment that meets or exceeds the requirements! If you’ve purchased product safety test equipment that specified a Rockwell hardness requirement, and you didn’t purchase it from us, chances are you’re using a piece of test equipment that DOES NOT meet the requirements.

CAUTION!:

ED&D is the only company in the world currently supplying safety products that actually meet or exceed the specified Rockwell hardness’s that are called for in the standards. Manufacturing to these specifications is an extremely difficult process. In addition, we rely on external laboratories that specialize in Rockwell hardness to verify and certify our results. These are corners our competitors’ often cut, but are vital toward providing equipment that meets or exceeds the requirements! If you’ve purchased product safety test equipment that specified a Rockwell hardness requirement, and you didn’t purchase it from us, chances are you’re using a piece of test equipment that DOES NOT meet the requirements.

-

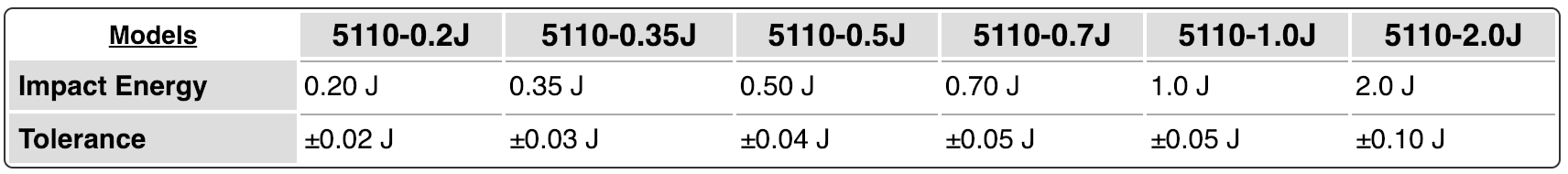

Series 5110 Spring-operated Impact Hammer

Read more -

Model F22.50 Impact Hammer

Read more -

Model F06.15 Tumbling Barrel Test Machine

Read more -

Model T16.10 Low Temperature RAM Impact Test Apparatus

Read more -

Model F28.13 Iron Drop Tester

Read more -

Model BMP-65 Bump Test Apparatus

Read more -

Model CTP-01 Coax Test Plug

Read more -

Model ITA-05 Impact Tester

Read more -

Model ITA-858 Copper Impact Tester

Read more -

Model SP Swing Pendulum / Impact Test Apparatus 1J

Read more -

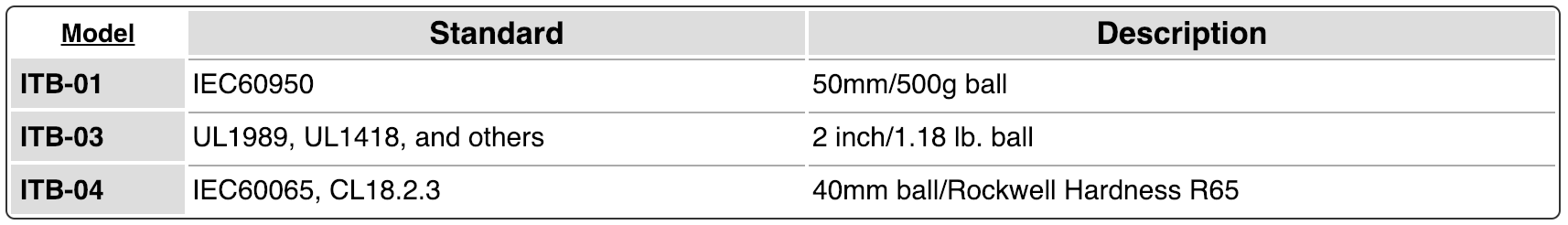

Series ITB Impact Test Balls

Read more -

Model BPH-639 1 Lb. Ball-Peen Hammer

Read more

company.

company.